The Complete Guide to Omnichannel Fulfillment for Enterprise Retailers

Omnichannel fulfillment is a strategic imperative for enterprise retail brands, particularly in the aftermath of the COVID-19 pandemic, as customer expectations have evolved.

Retailers can reap benefits from omnichannel fulfillment, including improved customer satisfaction, increased sales opportunities, and operational efficiencies.

Implementing omnichannel fulfillment requires integrating various channels, leveraging and integrating advanced technologies, and centralizing the order management function.

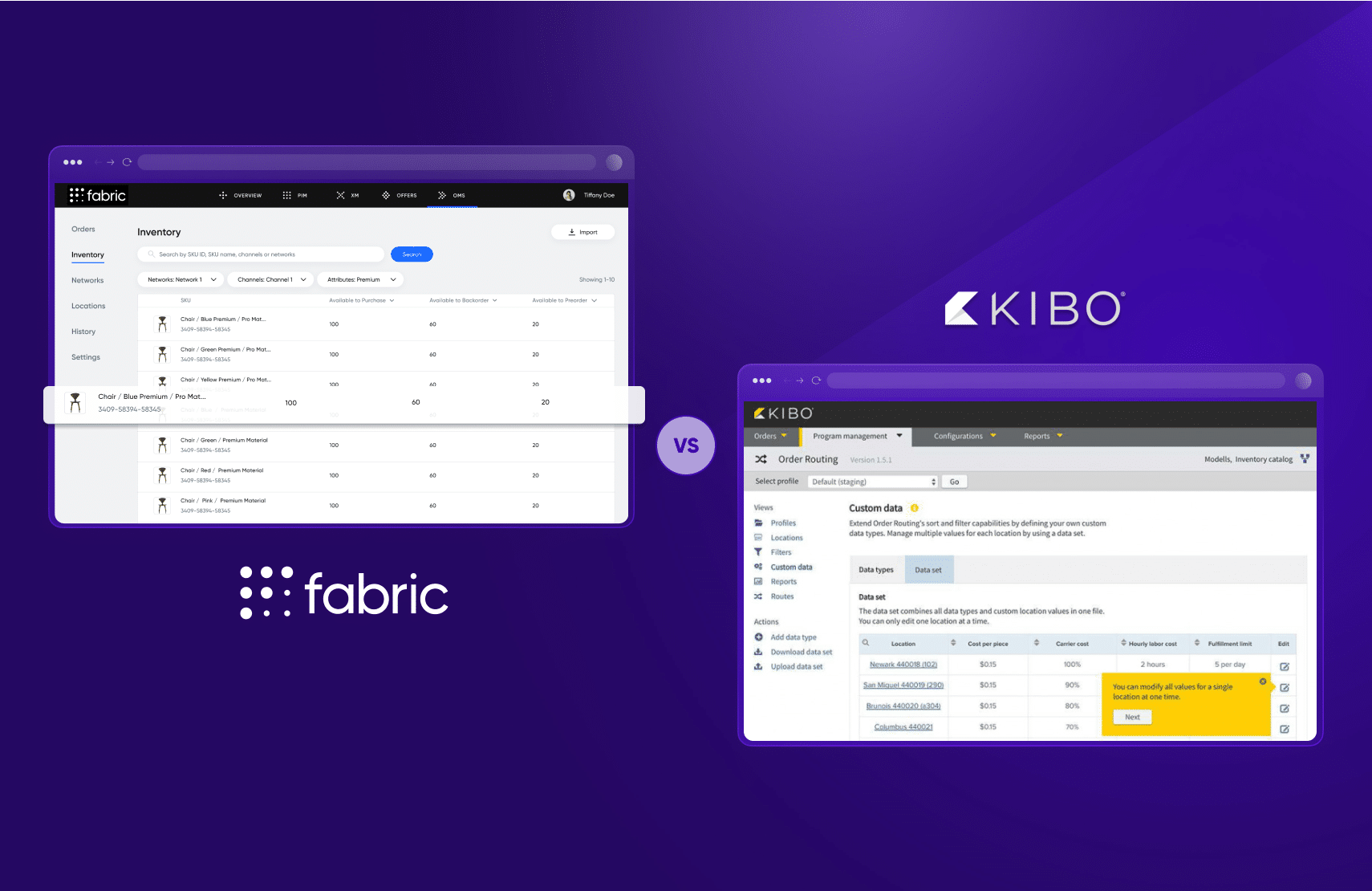

fabric OMS offers enterprise-level features and functionality to effectively manage orders, inventory, and fulfillment across multiple channels, enabling retailers to deliver a seamless customer experience.

During the COVID-19 pandemic, enterprise omnichannel retailers faced notable challenges (and opportunities) due to disruptions in the supply chain. According to The Federal Reserve Bank of New York’s Global Supply Chain Pressure Index (GSCPI), which includes key metrics such as shipping prices, delivery times, and backlogs, supply chain stress soared to severely elevated levels from 2020 to 2022.

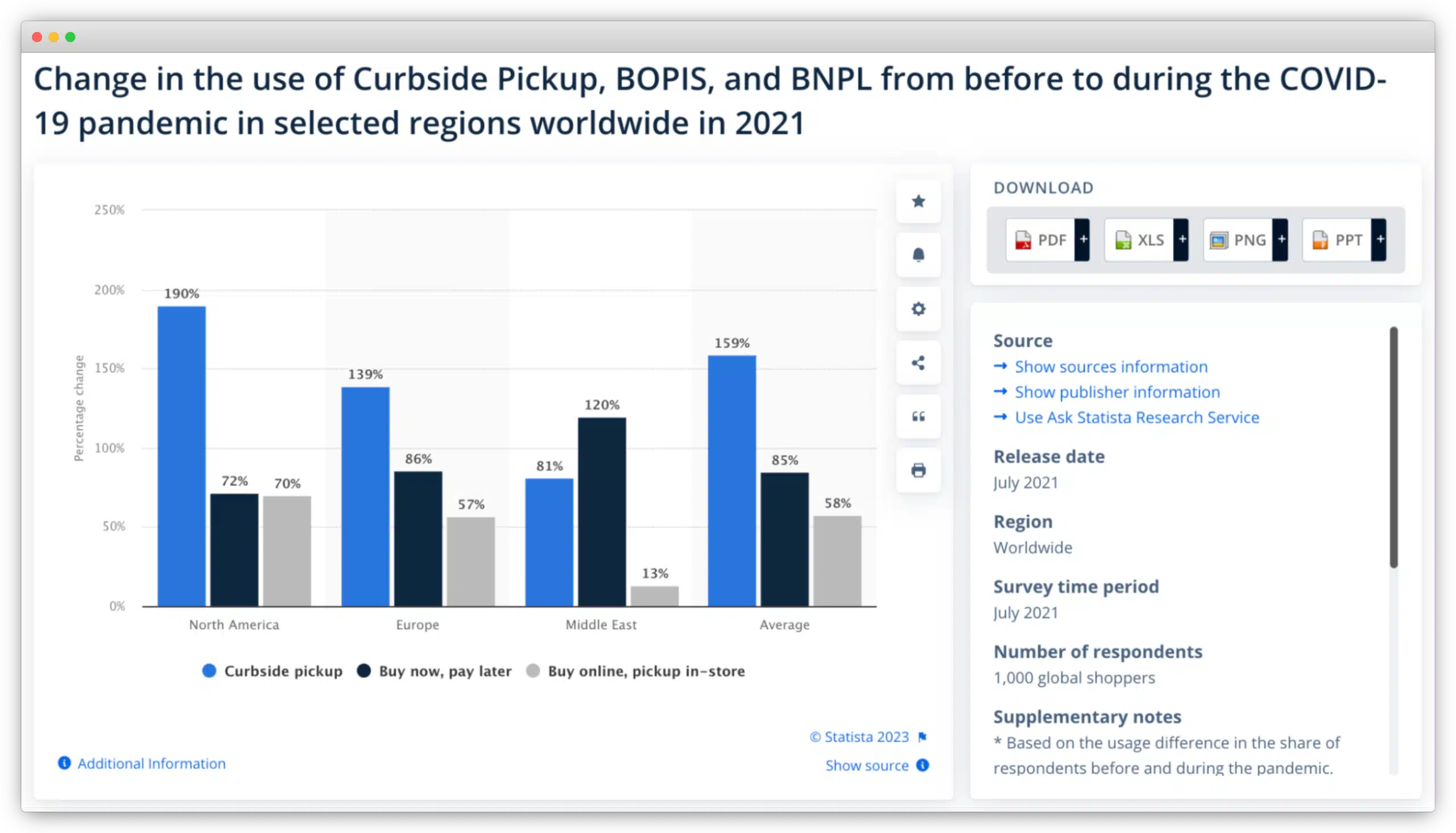

As a result, providing customers with omnichannel retail experiences became a requirement for survival. According to data from Statista, the use of curbside pickup and buy online, pick up in-store (BOPIS) grew significantly during the COVID-19 pandemic:

Today, omnichannel fulfillment has surpassed being just a fleeting trend and has solidified its position as a strategic imperative for modern enterprise retailers.

Businesses continue to diversify their fulfillment strategies to meet changing customer expectations and market dynamics. By implementing advanced order management systems (OMS) with distributed order management capabilities, retailers can not only centralize data, optimize inventory across channels, and automate order fulfillment processes, they can also offer different fulfillment options, including ship from store, buy online, pick up in store (BOPIS), and curbside pickup. As a result, customers enjoy greater convenience, speed, flexibility, and more personalized fulfillment experiences.

In this article, we will delve into the key components, technologies, and steps involved in successfully implementing omnichannel fulfillment for enterprise businesses. Let’s dive in!

What is Omnichannel Fulfillment?

Omnichannel fulfillment is a strategy that enables enterprise retail brands to seamlessly fulfill customer orders using connected inventory from any channel or combination of channels. This differs from multichannel fulfillment, where each channel operates independently and may have separate inventory and fulfillment processes.

For example, to create a true omnichannel commerce experience, businesses may offer store fulfillment options such as buy online and pick up in-store (BOPIS or click and collect), curbside pickup, or have items shipped from a nearby store. Not only does this flexibility enhance the customer experience, retailers also benefit from improved operational efficiency and reduced complexities by breaking down silos and creating a streamlined approach to order fulfillment.

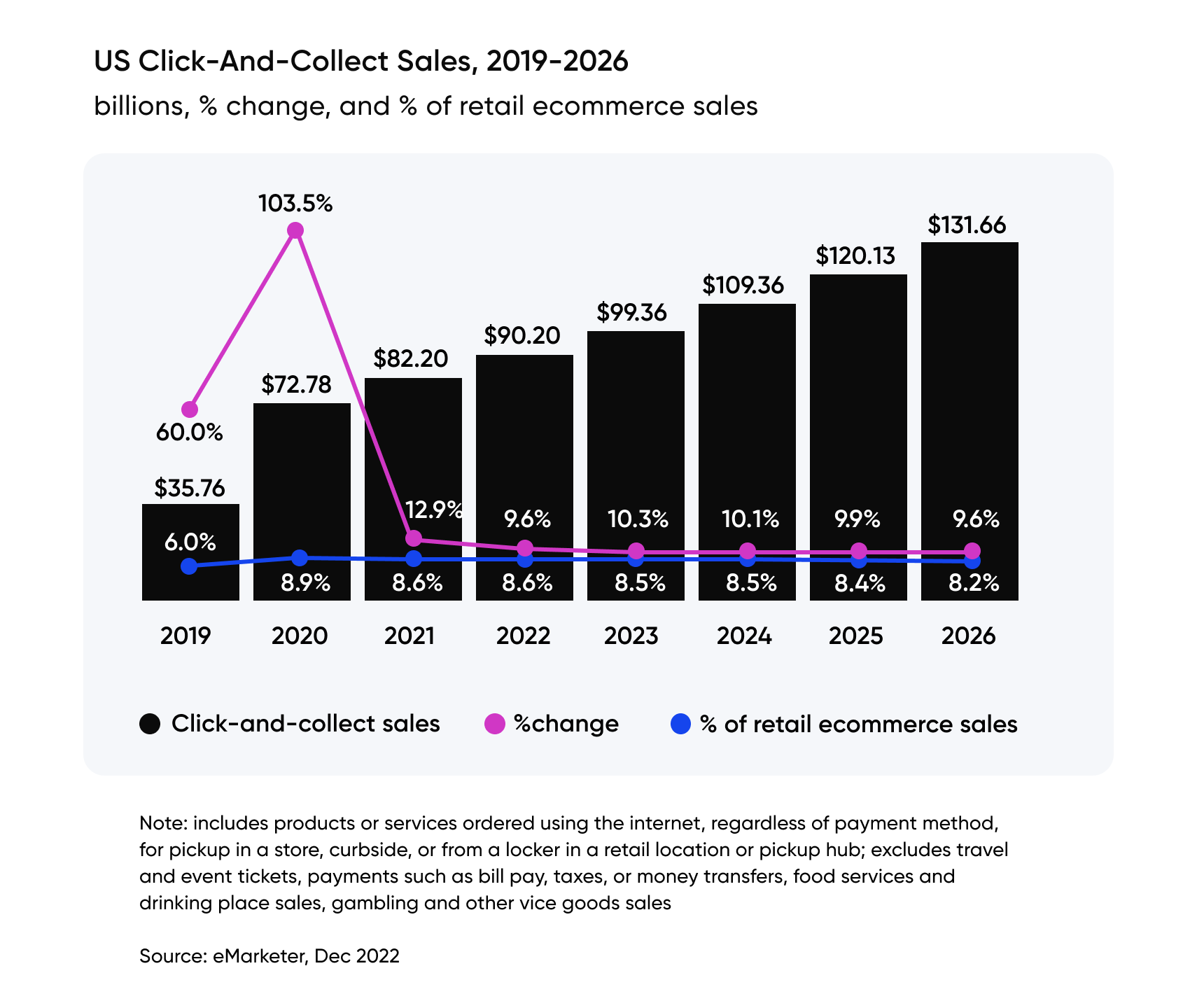

To successfully implement omnichannel fulfillment, retailers generally need to integrate an order management system (OMS) for inventory management, order routing, fulfillment processes, and customer communication. By synchronizing the various aspects of the retail supply chain, retailers can speed up the fulfillment process, and optimize operations. According to Insider Intelligence, U.S. BOPIS (click and collect) sales are projected to hit $99.36 billion in 2023 and rise to $131.66 billion by 2026:

What is an example of omnichannel fulfillment?

An example of omnichannel fulfillment is a fashion retailer that implements various types of fulfillment models to serve its customers across different channels.

For instance, a brand may offer BOPIS for customers who prefer to shop online and collect their purchases at a physical store location. Additionally, the brand may utilize a ship from store strategy to optimize inventory utilization and reduce shipping distances by fulfilling orders from the nearest store locations. Furthermore, the brand may also offer a ship to store option where customers can have their online orders shipped to a specific store for convenient pickup.

By leveraging omnichannel fulfillment strategies, a clothing brand can bridge the gap between online and offline channels. Providing convenient and flexible fulfillment options not only improves operational efficiency but also enhances the overall customer experience, leading to increased conversions and higher levels of satisfaction.

Benefits and Challenges of Omnichannel Fulfillment

Benefits

Increased conversion

By offering multiple fulfillment options, retailers can capture a broader customer base and reach new market segments. Customers who prefer in-store pickup may be enticed to make additional purchases while visiting the store, increasing foot traffic. Similarly, online shoppers who prefer home delivery have the convenience to shop from anywhere.

On a recent earnings call, Bath and Body Works’ CEO highlighted the fact that dual channel customers spent 3x more than single channel customers. By increasing dual channel customer penetration by 1%, they estimated they could drive additional sales of up to $50 million. Omnichannel fulfillment expands sales opportunities and boosts revenue potential.

Reduced costs

With fulfillment orchestration, retailers can optimize their inventory management by leveraging stock from multiple sources. By integrating inventory across stores, warehouses, and suppliers, retailers can efficiently fulfill orders and minimize stockouts and overstocking to avoid order cancellations. This improves inventory turnover, reduces carrying costs, and maximizes the utilization of available stock.

Inventory management also reduces costs per order. Real-time visibility and proactive communication can minimize the number of contacts per order, also known as WISMO (where is my order) inquiries, resulting in less support tickets and reduced costs for customer service operations.

Improved operational efficiency

Implementing effective omnichannel fulfillment processes with a modern OMS can streamline operations and reduce inefficiencies. By integrating order management systems, inventory tracking, and fulfillment processes, retailers can automate workflows and eliminate manual errors. This results in faster order processing, accurate inventory visibility, and improved overall operational efficiency.

Challenges

High total cost of ownership (TCO)

Implementing and maintaining an omnichannel fulfillment strategy may involve significant upfront and ongoing costs. Leading enterprise OMS platforms like IBM Sterling and Manhattan OMS are great for businesses that have massive technology budgets and large developer teams, but total cost of ownership (TCO) can quickly soar higher and force businesses to pay an e-commerce tax. Retailers need to carefully assess the return on investment (ROI) and may want to consider the long-term benefits of modular and scalable order orchestration software for omnichannel fulfillment.

Integration complexities

Integrating systems, such as e-commerce platforms, inventory management, order management, and fulfillment systems, can be challenging—especially without headless and microservices architecture. Omnichannel retailers require data and API orchestration to connect and manage disparate services, which allows for seamless data synchronization and real-time visibility across channels. Integration complexities may require dedicated resources, expertise, and technology investments.

Real-time inventory accuracy and management

Maintaining accurate inventory across multiple channels is crucial for successful omnichannel fulfillment. Traditionally, businesses relied on batch updates to reconcile inventory, resulting in delays, outdated info, and discrepancies between actual stock levels and what is shown in the system.

Developing an aggregated view of inventory across channels gives merchants the flexibility to orchestrate fulfillment and support convenient delivery and pick-up options for customers. Retailers must also ensure that inventory levels are updated in real-time to prevent overselling or stockouts. Inventory management becomes more complex when products are shared across different channels, requiring an OMS with robust inventory management capabilities to view, track, and manage stock accurately.

Is Omnichannel Fulfillment Right for Your Retail Enterprise?

“As a consumer, when I go on the retailer’s website or app, I expect to see availability, a connection to what’s in the store, and a way to order things that I can pick up in store.”

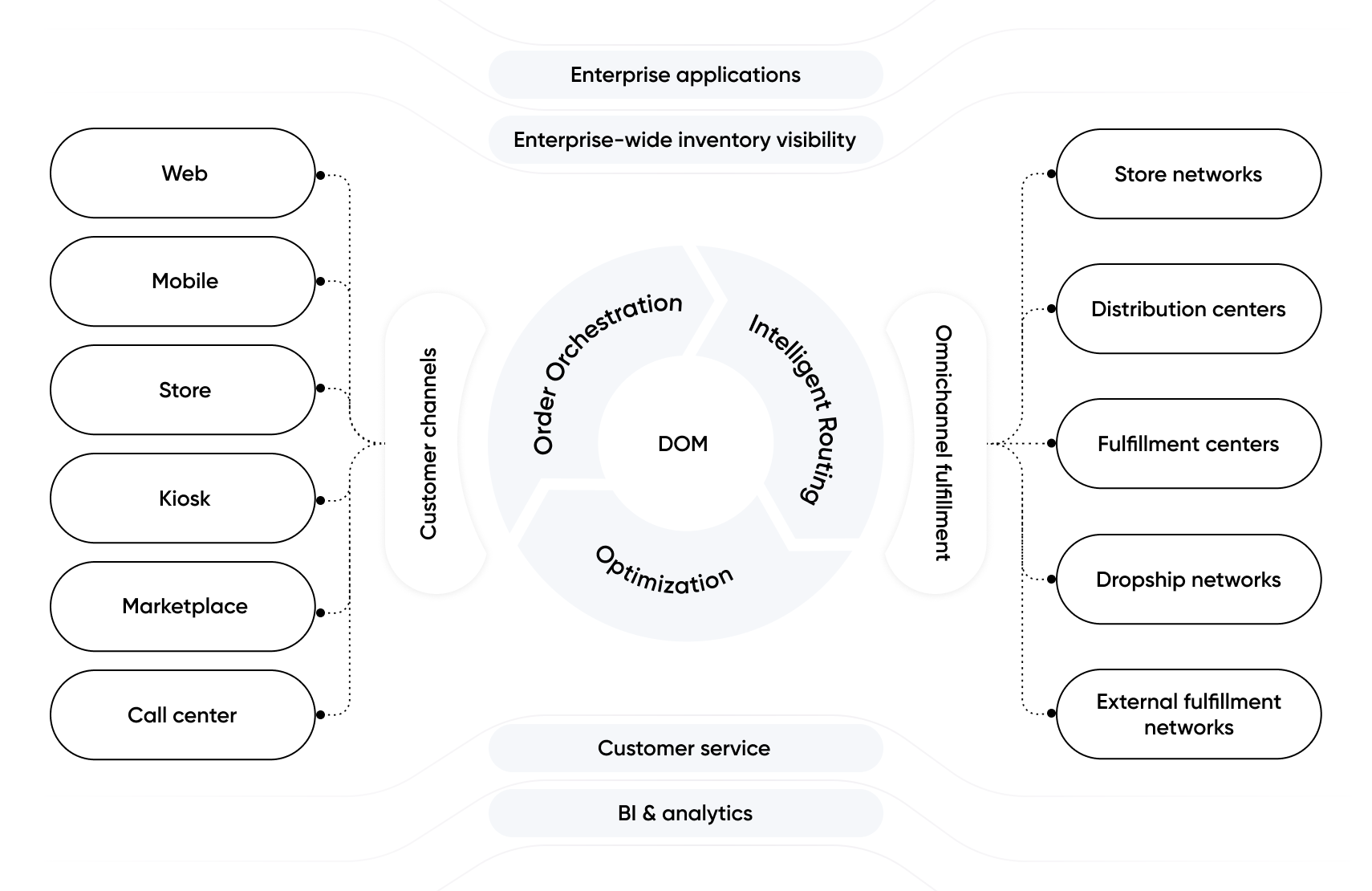

Omnichannel fulfillment operates through the integration of various channels and processes to deliver a seamless fulfillment experience. A centralized Order Management System (OMS) with distributed order management (DOM) capabilities plays a pivotal role in consolidating data and managing inventory, orders, and customer information across channels.

DOM

A distributed order management (DOM) system is order management software that utilizes order fulfillment logic (OFL), or logic-based rules, to orchestrate and optimize the order fulfillment process. This enables retailers to gain real-time visibility into stock levels, which in turn allows them to optimize inventory management, improve operational efficiency, as well as prevent common problems such as overselling, stockouts, order cancellations, and inaccurate product availability information.

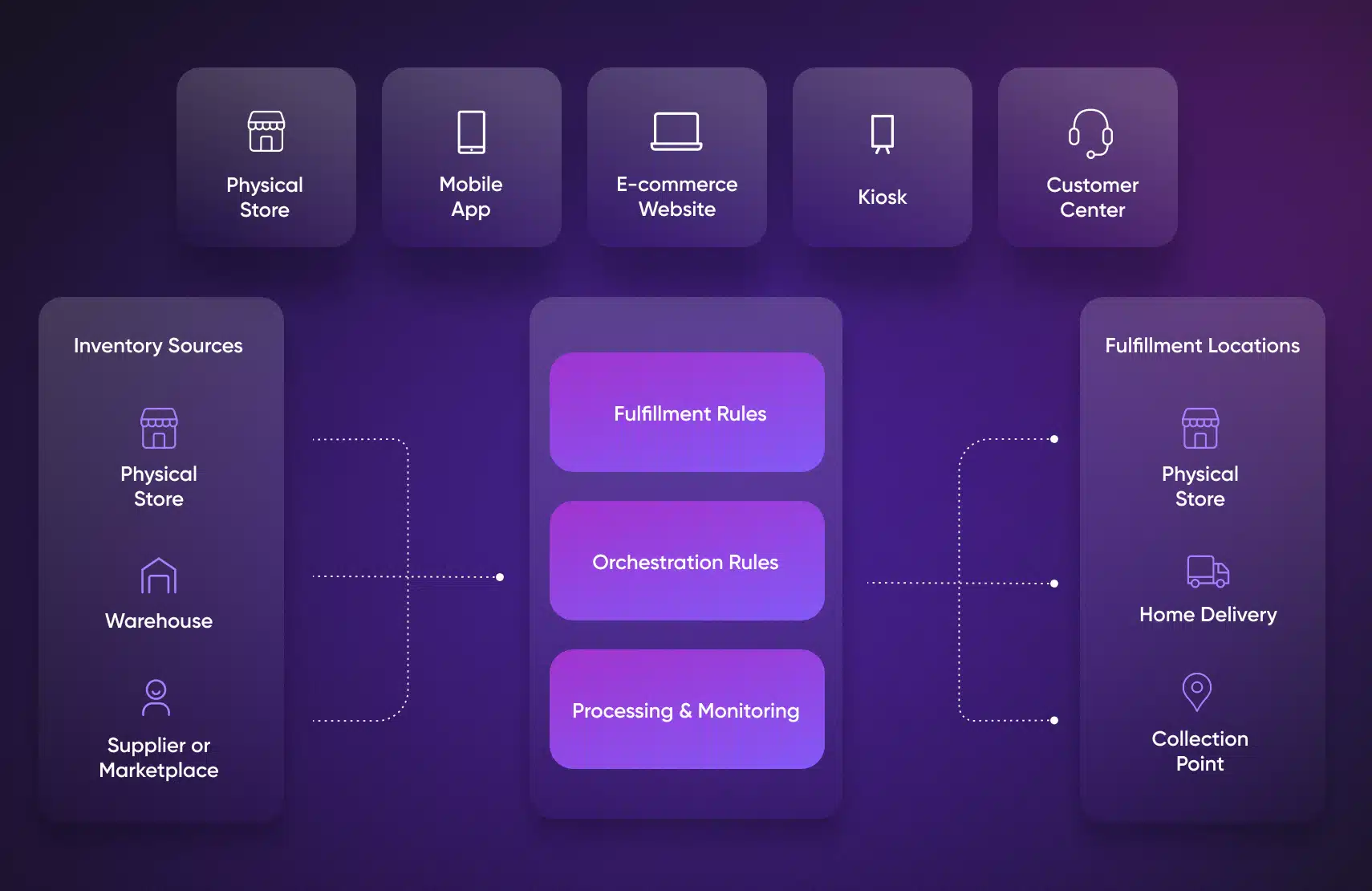

OFL also allows retailers to route orders to optimal locations, exert control over inventory, make informed decisions, and efficiently allocate resources for order fulfillment. The following illustration shows a modern OMS model with DOM capabilities:

With omnichannel fulfillment, a DOM system will simply route the order to the most suitable fulfillment location based on factors like inventory availability, proximity, and capacity. This could involve shipping from a warehouse, fulfilling from a nearby store, or leveraging dropshipping from suppliers. The OMS also facilitates order tracking, providing customers with visibility into their order status across channels.

Order processing workflow

When a customer places an order, it will follow this typical workflow for order processing:

- An order is placed on an e-commerce site, mobile app, or other digital sales channel.

- The payment is validated through a payment gateway and the order is recorded and accepted through an OMS.

- The omnichannel fulfillment location receives the order from the OMS or warehouse management system (WMS).

- The product is picked and packed by the warehouse staff or store associates, depending on fulfillment location.

- The order is shipped to the customer or is prepared for in store pickup or curbside pickup.

- If the customer wants to return the order, a refund and return process is initiated.

To ensure smooth omnichannel fulfillment, accurate and synchronized inventory management is vital. Seamless communication between departments and locations within the retail organization is also crucial for efficient coordination and execution of fulfillment activities.

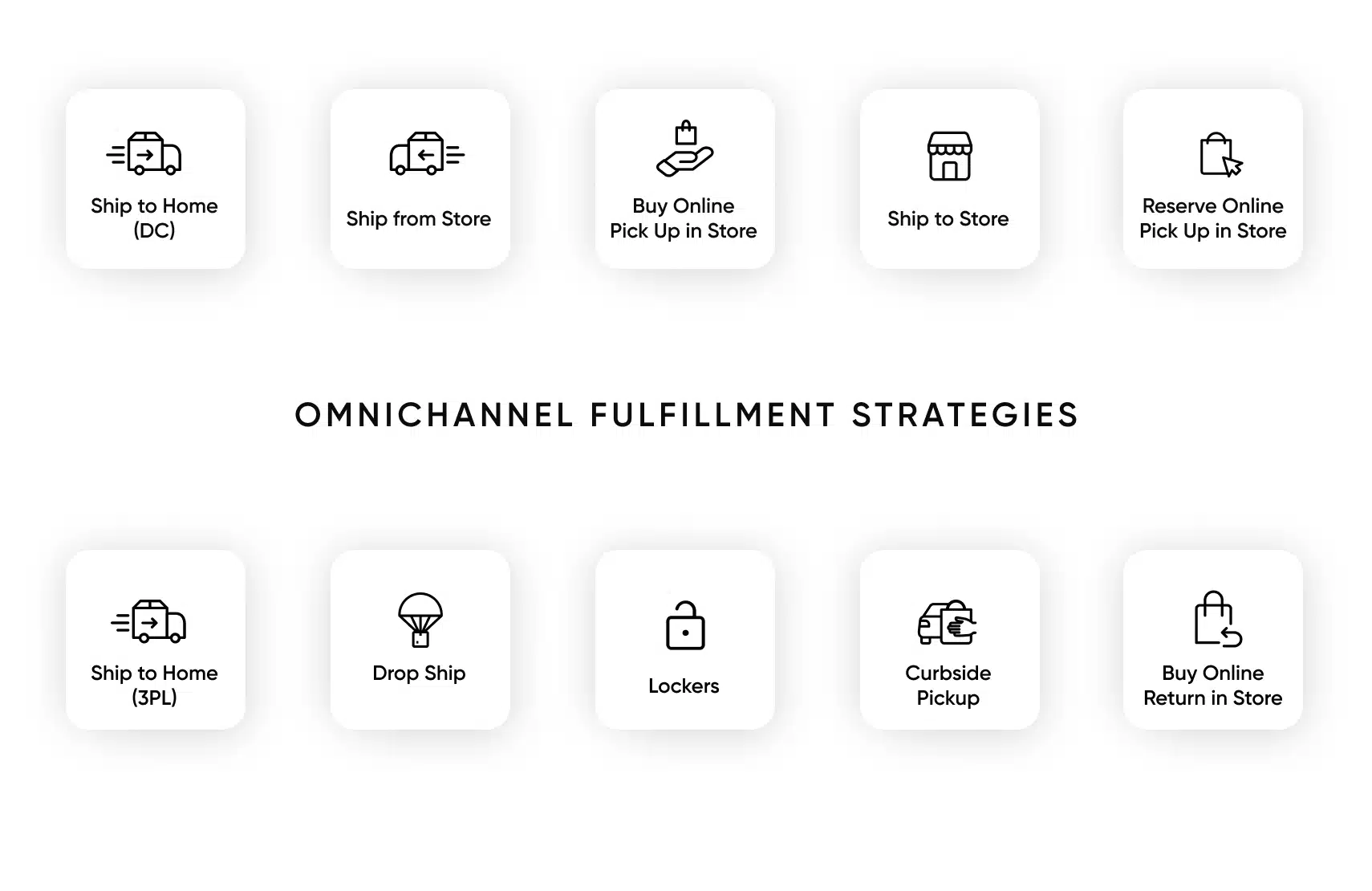

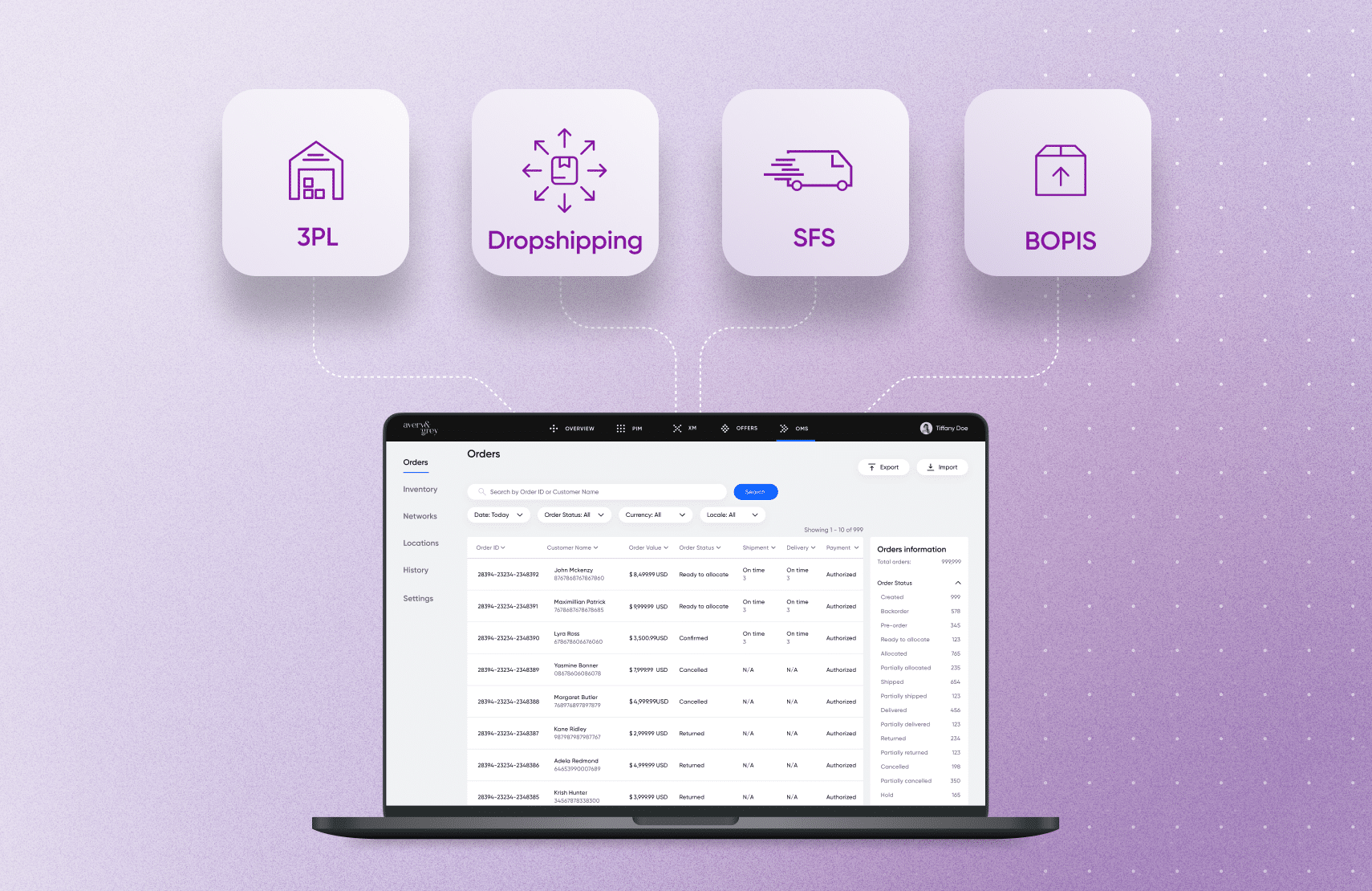

Trending Enterprise Omnichannel Fulfillment Strategies

There are many different types of omnichannel fulfillment models that retailers can adopt to seamlessly fulfill customer orders across multiple channels. These models integrate various sales channels, inventory sources, and fulfillment methods to provide a cohesive and consistent customer experience. Here are a few of the key types of omnichannel fulfillment strategies retailers use today:

Ship to home

Ship to home refers to the method of delivering products directly to the customer’s residential address. It offers convenience and flexibility and eliminates the need to visit a physical store.

Buy online, pick up in store (BOPIS)

Customers can purchase products online and pick them up at a physical store location of their choice. Shoppers get the convenience of online shopping combined with the immediacy of in-store pickup. Customers can save on shipping costs and have the option to inspect the products before taking them home.

Lockers

Lockers are self-service pick-up locations typically located in public areas such as shopping centers or transit stations. Customers can have their online orders delivered to these secure lockers and retrieve them at their convenience. Lockers provide a contactless and convenient fulfillment option for customers.

Ship from store

Orders placed online are fulfilled and shipped directly from nearby store locations, utilizing the store inventory for efficient and quick delivery.

Ship to store

Customers can have their online orders shipped to a specific store for convenient pickup, leveraging the existing store network for order fulfillment. Customers can select the most convenient location to collect their purchases.

Dropshipping

In this model, the retailer transfers customer orders and shipment details to the manufacturer or a third-party supplier who then directly ships the products to the customers. It allows retailers to offer a wide range of products without the cost of buying and managing inventory.

Curbside pickup

Curbside pickup allows customers to order online and collect their purchases without entering the store. Retailers designate specific curbside areas where customers can drive up, notify the store of their arrival, and have their orders brought out to their vehicles. This contactless fulfillment option gained popularity during the pandemic and offers convenience and safety.

Warehouse fulfillment

Traditional fulfillment model where orders are processed and shipped from a central warehouse or fulfillment center.

Third-party logistics (3PL)

Retailers partner with external logistics providers who handle various aspects of fulfillment, including warehousing, inventory management, and order processing across multiple channels. 3PL partners can streamline fulfillment operations and improve efficiency.

Hybrid models

Hybrid models combine different fulfillment models to leverage the strengths of each approach and optimize the fulfillment process based on specific products, locations, or customer preferences.

By implementing different types of omnichannel fulfillment strategies, retailers can offer customers a range of options for receiving their purchases, enhance convenience, and reduce delivery time. The choice of the omnichannel fulfillment model depends on the retailer’s specific business needs, customer expectations, and operational capabilities.

6 Steps to Successfully Scale Omnichannel Fulfillment for Your Enterprise Business

1. Select an OMS

The first step is to choose an OMS with DOM capabilities that supports omnichannel fulfillment. Look for features such as control over order lifecycle management, returns and refunds, inventory visibility and controls, and the ability to handle pre-orders and backorders, fulfillment optimization, and different omnichannel fulfillment options.

2. Integrate systems

Microservices architecture allows you to establish seamless integration between your OMS and other critical systems through the use of APIs, such as an e-commerce platform, enterprise resource planning (ERP) system, accounting system, and warehouse management system. This will ensure that data flows smoothly between these systems to provide accurate inventory visibility and order updates across channels.

3. Configure and customize your OMS

Configuration rather than code is critical for allowing operators with little to no coding expertise to optimize order fulfillment. A modern OMS platform should allow you to configure and customize the system according to your specific business needs. You can define rules for advanced order routing, inventory allocation, and fulfillment based on factors like location, inventory availability, and customer preferences. Fulfillment logic should be pulled from inventory data, product data, order data, and facility data.

4. Enable inventory visibility and availability

In the past, businesses faced challenges with batch inventory updates that led to delays, outdated information, and discrepancies between actual stock levels and system records. A modern OMS should provide real-time monitoring and updates of inventory availability throughout the retail supply chain.

With complete visibility across sales channels, fulfillment centers, and customer service channels, you can display precise available-to-promise (ATP) quantities on your storefront using an inventory availability storefront API endpoint. ATP represents the inventory ready for sale, excluding any allocated for existing orders, and helps businesses maintain optimal inventory levels to minimize costs associated with overstocking or understocking while meeting future demand through data-based forecasts.

5. Define fulfillment options

Determine the fulfillment options you want to offer customers, such as ship-from-store, in-store pickup, or home delivery. Configure the OMS to handle these options and ensure smooth order processing and fulfillment regardless of the chosen channel.

6. Test, Launch, and Monitor

Once you conduct thorough testing of the OMS and its integrations with other systems, you can launch it for live operations. Companies should monitor key performance indicators, such as order fulfillment time, inventory accuracy, customer satisfaction, and sales conversion rates. By regularly reviewing these metrics, you can identify areas where the OMS can be further optimized. Several common key performance indicators (KPIs) include:

- Cost per order: This metric assesses the total expenses associated with fulfilling a single order, including processing, packaging, and shipping costs.

- Rate of returns: This KPI measures the percentage of products that are returned by customers, indicating the effectiveness of order fulfillment and product quality.

- Order fulfillment cycle time: This metric tracks the duration between when a customer places an order and when it is delivered to them, providing insights into the efficiency and speed of the fulfillment process.

- Perfect order rate: This KPI evaluates the percentage of orders that are completed without any returns or issues, reflecting the overall accuracy and effectiveness of the fulfillment process.

fabric OMS: A Distributed Order Management System for Omnichannel Retail

fabric OMS is an advanced DOM system that’s purpose-built for enterprise omnichannel retail. With centralized order processing, real-time inventory visibility, and advanced order routing, it enables businesses to efficiently manage orders across multiple channels and gives retailers the flexibility to support various fulfillment options such as BOPIS and store fulfillment.

Additionally, fabric OMS is built on state-of-the-art multitenant architecture, allowing SaaS customers to unlock a range of benefits including significantly reduced costs, enhanced flexibility, and improved efficiency.

If you’re interested in learning more about fabric OMS and how it can enhance operational efficiency, improve order accuracy, and deliver seamless omnichannel experiences to your customers, schedule a demo with our team here.

Enterprise Omnichannel Fulfillment FAQ

What is omnichannel fulfillment in retail?

Omnichannel fulfillment in retail refers to the strategy of seamlessly integrating and fulfilling customer orders across various channels, such as physical stores, online platforms, and mobile apps, to provide a cohesive retail shopping experience.

What’s the difference between omnichannel and multichannel fulfillment?

The main difference between omnichannel and multichannel fulfillment is that omnichannel focuses on providing a consistent and interconnected customer experience across all channels, while multichannel fulfillment simply refers to utilizing multiple channels for order fulfillment without the same level of integration and consistency.

Can you outsource omnichannel fulfillment to a 3PL?

Yes, enterprise retailers have the option to outsource omnichannel fulfillment to third-party logistics providers (3PLs) who specialize in managing and coordinating the fulfillment process across different channels.

Is omnichannel fulfillment worth it for enterprise retailers?

Omnichannel fulfillment can be highly beneficial for enterprise retailers as it enables them to meet the evolving demands of customers, increase sales opportunities, and improve operational efficiency.

Digital content editorial team @ fabric.