How Drop Shipment Order Management Works

30% of online retailers use dropshipping as their primary source of order fulfillment.

Drop shipment order management increases customer retention by rerouting orders to suppliers instead of marking products as “out of stock.”

Retailers selling on multiple marketplaces can use OMS integration to sync customer data into one central hub.

Retailers can streamline their drop shipment process via a centralized platform with fabric OMS.

Drop shipment is when retailers fulfill orders via a third-party supplier who ships products directly to the customer on their behalf. With dropshipping, retailers do not touch, store, or package the products themselves. Today, 30% of e-commerce retailers use dropshipping as their primary order fulfillment method.

In this post, we’ll discuss the pros and cons of drop shipment order management and how it works for retailers and suppliers.

Features of Drop Shipment Order Management

Pros of drop shipment order management

Reroutes customer orders

When a customer places, an order management software (OMS) checks the inventory levels. With drop shipment order management, if the retailer does not have enough units, the order is redirected to a supplier’s warehouse, where more units are available, instead of marking the item as “out of stock.”

Eliminates packaging costs

Packaging a product can cost up to 15% of the price of the product. Drop shipment order management sends orders to suppliers, which incur these costs as they package and deliver orders. As a result, retailers can earn a profit from the transaction. For example, those who use eBay to fulfill drop shipment orders make $2.67 on every sale.

Reduces order processing time

The traditional dropshipping procedure involves forwarding the customer invoice to the supplier via mail to process the order. This method is slow. In drop shipment order management, customers’ orders automatically go to the supplier for immediate processing.

Scale without risking inventory

When a business grows, maintaining orders efficiently and accurately becomes more difficult. With drop shipment order management, however, inventory data of new warehouses are collected without altering the existing data of old warehouses.

RevCascade is a dropship solution, for businesses that want to scale without risking inventory. The company provides a centralized platform that collects all drop shipment orders in one place and lets retailers track fulfillment statuses.

Cons of drop shipment order management

At the mercy of suppliers

Once the order is rerouted to the supplier’s order management software, your supplier is now in charge of delivering the customer’s order. Retailers depend on suppliers to fulfill the order and meet customer expectations. If customers are dissatisfied, they associate it with the retailer is responsible for resolving their post-purchase problems.

Order errors

One of the problems with order management software is that they sync at a slow rate. This is problematic for businesses that sell the same product from different brands.

For example, if a customer requests one Kleenex tissue, the OMS software may transfer the order to Kleenex, Angel Soft, and other brands. A wider digital footprint increases the probability of dropshipping errors, resulting in multiple suppliers packaging and sending out bulk orders.

How Drop Shipment Order Management Works for Retailers and Suppliers

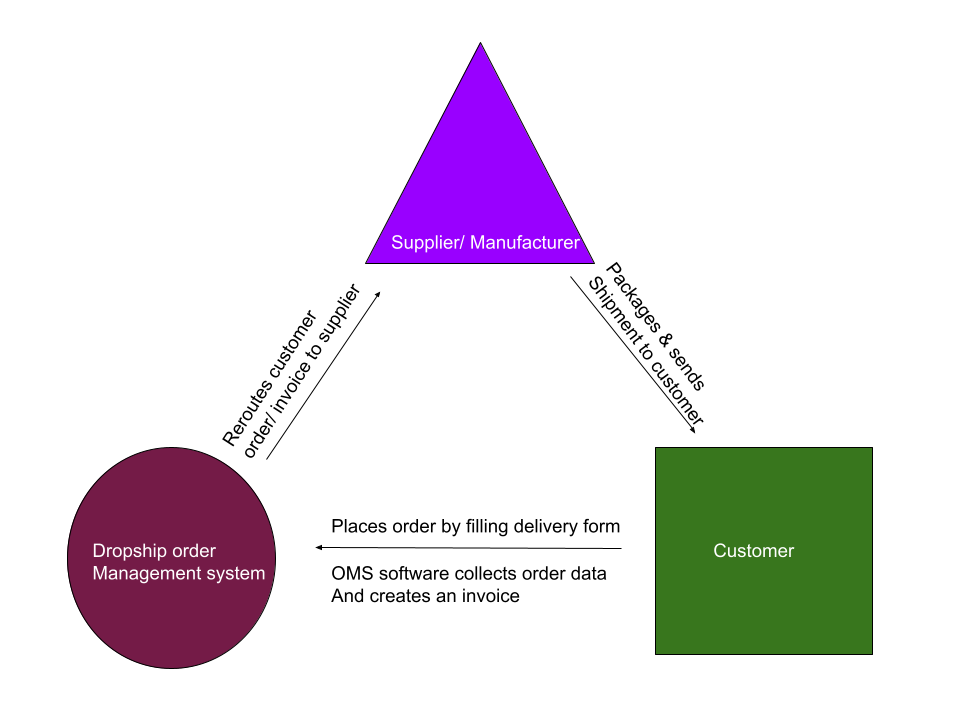

Here’s an overview of how the drop shipment order management process works:

- A customer places an order on a retailer’s channel.

- The retailer receives an order through the OMS software.

- The OMS software prepares an invoice for the order.

- The invoice is transferred from the retailer’s OMS to the supplier’s OMS through EDI.

- The supplier processes and prepares the items for shipment to the customer.

When a customer places an item on the retailer’s online store, the OMS software retrieves the order information and automatically creates an invoice. This invoice is transferred to the supplier’s OMS through electronic data interchange (EDI). It is a communication system that lets two businesses share information interchangeably. Through this communication process, the retailer’s dropshipping software synchronizes with the supplier’s software for rerouting customer orders.

At the final stage of the dropshipping process, the supplier is in charge of processing and preparing the order for shipment to the customer. Depending on the nature of the partnership between the supplier and retailer, the supplier may send the products in a custom package reflecting the retailer’s brand. But in most cases, the packaging is generic.

Tech advocate and writer @ fabric.